Structure of cast iron

The two most important types of cast iron are grey cast iron and spheroidal

graphite cast iron:

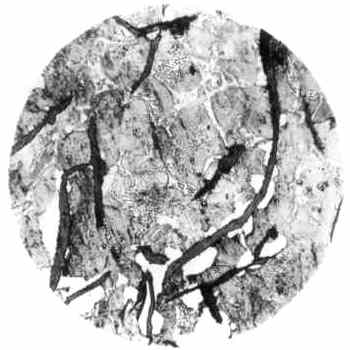

Grey cast iron

Structure: Graphite flakes in a iron matrix

Compressive stress: Excellent compressive strength and low elastic modulus

Wear behaviour: The friction coefficient is low (graphite lubrication)

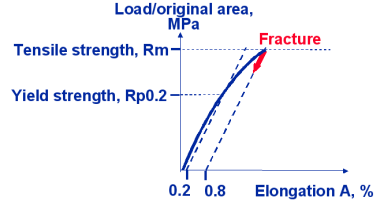

Brittleness: Percentage elongation after fracture is very low, extremely notch

sensitive

Strength: Tensile strength is relatively low ( in function of grade), no yield

point - no overload capacity

Machining / Cutting: Very good machinability for drilling and machining, cannot

be sheared

Oxyacetylene cutting is difficult.

Grey cast iron structure

Typical stress elongation curve for grey cast iron

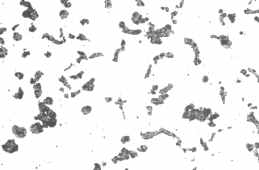

Spheroidal graphite cast iron

Structure: Spheroidal graphite in a iron matrix

Compressive stress: Excellent compressive strength, slightly more elastic than

steel

Wear behaviour: Similar to cast steel

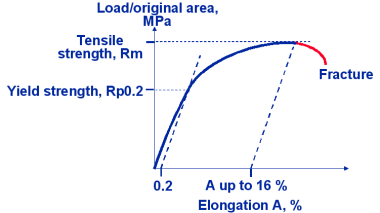

Brittleness: Plastic deformation (percentage elongation) after fracture is much

higher than for grey cast iron

Strength: Tensile strength up to 800 MPa, elastic limit is at least half the

tensile strength

Machining / Cutting: Very good machinability for drilling and machining, cannot

be sheared

Oxyacetylene cutting is difficult.

Spheroidal graphite cast iron structure

Typical stress elongation curve for spheroidal graphite cast iron

Typical components

Grey cast iron

- Heavy parts in general

- Machine bases

- Gears, heavy gear boxes

- Pulleys, transmission cases

- Housings, casings

- Machine guards

- Engine cylinder blocks and heads

- Furnace parts, moulds, glass moulds

- Cold cropping tools

- Valves, gates, pump bodies

Spheroidal graphite cast iron

- Heavy parts in general

- Machine bases

- Gears, crankshafts

- Pulleys

- Housings, casings

- Machine guards

- Heavy tubes, pipelines, fittings

- Cold cropping tools

- Stamping tools and dies

- Valve and pump bodies (steam, etc.)

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|