Believe in success and picture it in your mind (Kevin J. Alvares, India)

Training and Education:

Wear Management is the Swiss partener in the Leonardo Project VocTrainMaint (2009 - 2011.

Leonardo - VocTrainMaint

Industrial Maintenance Management:

Training Moduls

- 01. Importance of maintenance

- 02. Terminology - definitions

- 03. Life cycle aspects (product, equipement, system)

- 04. Maintenance objectives

- 05. Responsibility of Maintenance

- 06. Maintenance process

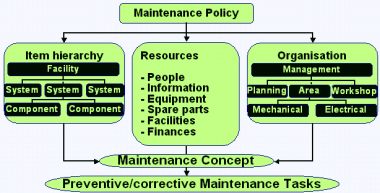

Interrelationship for Process Development

- 07. Maintenance support

- 08. Resource Management

- 09. Sub-contracting

- 10. Measurement, analysis and improvement, Repair

- 11. Continuous improvement

- 12. Safety and environment

Welding Metallurgy for Steel Welding

Training Moduls

- 21. Structure of Alloys

- 22. Work Hardening, Precipitation Hardening and Eutectoid Transformations

- 23. Metallography

- 24. Properties of Steels

- 25. Diagrams for Thermal Treatments

- 26. Thermal Treatments

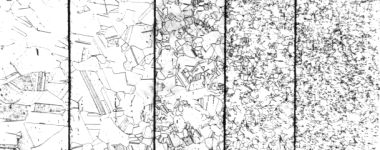

Different Grain Sizes after Annealing, with Annealing Twins

- 27. Weldability of Steels

- 28. Welding of Carbon Steels

- 29. Welding of low alloy steel

- 30. Welding of Chromium Steel

- 31. Welding of Austenitic steels

- 32. Welding of Special Steels

- 33. Heterogenious Welding

- 34. Welding Procedures

Engineering - Materials - Design:

- 41. Wear Management

- 42. Wear Management in CEMENT WORKS

- 43. Tool and dies in AUTOMOTIVE INDUSTRY

Maintenance and Repair Welding

Training Moduls

- 51. Maintenance and Repair Welding

- 52. Spare part reclamation technique

- 53. Heavy Maintenance

- 54. Procedures for Repair Welding and Coating

- 55. Welding Metallurgy

- 56. Welding Processes

- 57. How to write a Welding Procedure

- 58. Cast Iron Welding

- 59. Welding of Alloy Steel

- 60. Welding and Coating of Tool Steel

- 61. Coating by Welding, Brazing and Thermal Spraying

- 62. Brazing by Flame

- 63. Visual inspection

- 64. Health and Safety

Practical training in the workshop

Qualification of European Maintenance Technicians and Supervisors

CEN/TC319, EFNMS

Seminars and congresses on Industrial Maintenance

Congress Management

Best student !

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|